Theme: Catalysis and Reaction Engineering Technologies for a Sustainable Future

Euro Catalysis 2020

On behalf of the Organizing Committee, we take immense pleasure in inviting you to "8th International Conference on Catalysis and Reaction Engineering" scheduled during November 16-17, 2020 at Lisbon, Portugal.

Theme of the Conference: Catalysis and Reaction Engineering Technologies for a Sustainable Future

EURO CATALYSIS 2020 aims to bring together leading academicians, scholars, investigators, Chemical Engineering Researchers, industrialists and associated experts to exchange and share their experiences and research results on all aspects of Catalysis and Reaction Engineering Conference. It also provides a premier interdisciplinary platform for researchers, practitioners, and educators to present and discuss the most recent innovations, trends, and concerns as well as practical challenges encountered and solutions adopted in the fields of Catalysis and Reaction Engineering Conference.

Euro Catalysis 2020 discusses on novel subjects like Advances in Catalysis, Chemical Reaction Engineering, Environmental Catalysis and Nano Catalysis, Biocatalysis, Biotransformation and Organocatalysis, Reactor engineering, Green & sustainable catalysis, Advanced synthesis, Catalytic systems and new catalyst designing and many more. Sustainability is a concept which is used to differentiate methods and processes that can ensure the long-term productivity of the environment, so that even following generations of humans can live on the planet. Sustainability has environmental, social, and economic dimensions.. The conference also includes Keynote sessions by prominent personalities from around the globe in addition to both oral and poster presentations.

On behalf of Euro Catalysis 2020, we are glad to invite contributions from the enthusiastic academicians, industrialists, teachers, and scientists to organize International Symposiums/Workshops that are both empirical and conceptual in exploring new magnitudes of Catalysis and Reaction Engineering challenges for a sustainable tomorrow.

Why to attend?

· Conferences provide a great opportunity for networking for future collaborations where most people can help each other uncover ideas and spark inspiration.

· To learn and find new things in your discipline of interest

· Socialization and the culture factor, exploring new places and having fun

· Meet experts and influencers face to face

· Attending a conference allows you to grow and adds your research value

· Network with leaders and influencers from the scientific, academic and R&D communities

· Attending conferences grow your professional network

Target Audience:

Catalysis Researchers, Chemical Engineering Professionals, Research faculties, Academic Scientists, Chemical Engineering Students, Biochemical Engineers, Polymeric Engineers, Chemical Engineering Associations and Societies, Chemical laboratory professionals, Exhibitors, Business Entrepreneurs, Associations and Collaborations, Industry Professionals, Industrial experts, Scientists, Vice Presidents, Manufacturers, Research Associates, Brand Marketers, Advertising Agency Executives, Professors and Students from Academia.

Track 01 - Fundamentals and types of catalysis

Catalysis is used to increase the rate of a chemical reaction by adding a substance called as a catalyst. It is not consumed in the catalysed reaction it can also be used repeatedly. Because of this reaction very small amounts of catalyst are required to alter the reaction rate. Catalysis plays a major role in giving the society with fine chemicals, fuels, pharmaceuticals. It also helps the human kind in protecting environment. Now a days, in present scenario chemical industries mainly depends on catalysis. More than 80% of the chemical reactions are catalytic processes which mainly produces some of the materials like plastics, synthetic rubbers, fabrics, cosmetics etc. It involves catalytic processes, production of clean energy from the renewable energy sources, such as hydrogen for fuel cells and transportation fuels from non-edible biomass which are catalyst dependent processes. Catalysts are used in the production of polymers including adhesives, coatings, foams, textile and industrial fibres.

- Positive catalyst

- Negative catalyst

- Auto catalyst

- Homogeneous

- Heterogeneous

Track 02 - Biocatalysis and Biotransformation

It consist of two types actual and potential catalysis which are part of Biocatalysis and Biotransformation that includes whole cells or isolated components therefore natural and modified enzymes and catalytic antibodies for the synthesis of interconversion or degradation of chemical species. It is the chemical modification that is occurred by the influence of an organism or by the presence of enzymes in the biological system which is known as Biotransformation. The process of transformation of chemicals that are used in biological catalysts like enzymes, antibodies, cell constituents are called as Biocatalysis.The Enzymatic reactions and biotransformations are catalyzed by fungal enzymes are used in industry, agriculture, food technology, and medicine.

- Catalytic transformations

- Biocatalysts

- Biomedical engineering

Track 03 - Advanced Synthesis, Catalytic Systems and New Catalyst Designing

It is designed to stimulate the process by focusing on the development and application of efficient synthetic methodologies and strategies in organic and bio-organic pharmaceutical natural product macromolecular and materials chemistry that are used for Advanced Synthesis & Catalysis. The targets of synthetic studies which range from the natural products and pharmaceuticals to macromolecules and organic materials are used. While catalytic methods mainly depends on metal complexes or enzymes plays an increase the role in for achieving synthetic efficiency of all areas of interest to the practical synthetic chemist. Advanced Synthesis and Catalysis includes synthesis design reaction techniques and separation science and process development.

- Catalyst design & synthesis

Track 04 - Industrial Catalysis and Process Engineering

Catalysis plays an important role in the chemical industry and industrial research. For Different catalysts are in the constant development to fulfill the economic, political and environmental demands. While using a catalyst, it is possible to replace a polluting chemical reaction with a more environmental friendly alternative. Today and for the future, this may take a vital role in the chemical industry. In addition, to this it’s important for a company/researcher to pay attention to the market development. If a catalyst is not continually improved by the company, then another company might take progress in research on that particular catalyst and can gain market share value. A new and improved catalyst can be a huge advantage for a competitive manufacturing cost for a company. That it’s extremely expensive for a company to shut down the plant because of an error in the catalyst, so that the correct selection of a catalyst or a new improvement can be key to industrial success.

- Industrial chemicals and fine pharmaceuticals

- Industrial applications of Green Chemistry

Track 05 - Reaction engineering

Reaction engineering is mainly important for chemical engineering or industrial chemistry is dealing with the chemical reactors. Then Frequently these term relates specifically to the catalytic reaction systems where both a homogeneous or heterogeneous catalyst is present in the reactor. a reactor is not present by itself at Sometimes, but rather it is integrated into the process, then the issue of solvent effects on reaction kinetics, and it is also considered as the integral part .Chemical Reaction Engineering accept the modern chemical industry and aim is to achieve high-quality products and minimize the unwanted by-products which is particularly important for Selectivity in the reactor by processes in which by-products cause environmental problems.

- Molecular simulation and theoretical modeling

- Catalyst poisoning, deactivation & stability

- Kinetics, and reaction pathways

- C-C bond formation

- C-H bond activation

- Selective oxidation & hydrogenation

Track 06 - Green and Sustainable Catalysis

Catalysis in Green Chemistry and Engineering is related to the use of catalyst in green process and sustainable engineering, and then it’s mainly related to the catalyst synthesis, characterization and its applications which are primarily to reduce waste associated with the usage of materials and energy in a given process in consonance. To develop a sustainable production processes and which reduces the impact on the environment to an acceptable level and that allows self-depuration processes of the living environment. Catalytic agents enables for a broad range of chemical reactions that are fundamental to Industrial and consumer products from plastics to pharmaceuticals, solvents to soap, and fuels to food.

- Green nanotechnology

- Green synthesis

Track 07 - Organometallics, Organocatalysis and Bioinorganic Chemistry

Organometallic chemistry which deals with the study of organometallic compounds and the chemical compounds. It contains atleast taking a one chemical bond between the carbon atom of an organic molecule and a metal, and it includes alkaline, and alkaline earth, and transition metals, and it broadened to include a metalloids like boron, silicon, and tin, From a side of bonds to organyl fragments and bonds to 'inorganic' carbon, like carbon monoxide, cyanide, or carbide, are generally considered as organometallic. Associated compounds such as transition metal hydrides and metal phosphine complexes are generally included in organometallic compounds. The term "metalorganic compound" refers to metal-containing compounds lacking direct metal-carbon bonds contains a organic ligands. The organometallic chemistry combines the aspects of traditional inorganic and organic chemistry in these field.

- Recent developments in biocatalysis, organic and inorganic catalysis

- Agrochemical

- General Properties of Transition Metal Organometallic complexes

- Carbonyls and Phosphine Complexes

- Complexes of n-bound ligands

- Reaction Mechanisms

- Physical Methods in Organometallic chemistry

- Multiply-Bonded Ligands

- Metathesis

Track 08 - Chemical engineering

The branch of engineering specifies about the study and principles of chemistry, physics, mathematics, biology, and economics to effective use, and produce, design, transport and transform energy and materials, Chemical engineers work can range from the use of Nano-Technology and Nano-Materials in the laboratory to a large-scale industrial processes that transform chemicals, raw materials, microorganisms, living cells and energy into useful methods of products.Chemical engineers are involved in many aspects of plant design and operation, which includes safety and hazard assessments, and the process design and modeling, analysis, nuclear engineering, control engineering,biological engineering,chemical reaction engineering,construction specification, and operating instructions are involved.

- Plant design and operating instructions

- Safety and hazard assessments

- Process design and analysis

- Control Engineering

- Chemical Reaction Engineering

- Construction specifications

Track 09 - Novel Concepts of Catalysis and Applications

The chemical process industry aspects a marvelous task of delivering, growing and always more demand of global population with the products we required. The average effectiveness at which resources are changed into the final products are still dramatically low and which is almost clear solution to perform chemical conversions at much higher yields and selectivity, this is where active and selective catalysts are efficient chemical reactors.It plays an important role for presenting that how to enhance the efficiency of catalysts and reactors, and The most important developments in the field of chemical reactor engineering and industrial catalysis. In addition, many ways of improving efficiency, activity, selectivity, and improved methods for scale–up, modeling and design are presented in a solid manner.

- Molecular Modeling

- Zeolites

- Catalysis at room temperature

- Biocatalysis

- Catalysis for sustainability

- Structured reactors including membrane and micro channel reactors

- Switching from batch to continuous reactors

- Application of alternative energies and process intensification

Track 10 - Novel Reactors & Process Intensification

Novel reactor deals with process intensifications tools like capillary reactor, then it also deals with the chemical process industries, and due to this distinct high specific interfacial area are obtainable from heat and mass transfer, that increases the transfer rates and improves the safety process. It provides a motivation for exploring the three similar tools, like capillary micro reactor, spinning disc, and rotating tube reactors. Process intensification is a chemical and process design pathway that leads to considerably smaller, cleaner, safer and more energy-active process technology. Beyond the chemical and process industries, and deals about the developing successful PI solutions and which deliver savings and ability which demands the engineers to work with important-edge process technologies and these involved in research and development of chemical process, pharmaceutical, bioscience systems, and environmental.

Track 11 - Academic-Industrial Catalysis Research

Most of the products are produced from the chemical and petroleum industry utilizes a catalysts to increase the rate of reaction and refinement to the desired products. Catalysts are also broadly used to reduces a harmful byproduct pollutants in environmental applications. Enlarge the reaction rates and converts to the higher production volumes at lower temperatures with smaller and less exotic materials of construction needed. While a highly selective catalyst is used, and large volumes of desired products are produced with essentially no undesirable byproducts. Diesel, Gasoline, home heating oil, and aviation fuels owe the performance quality to catalytic processing used to upgrade the crude oil.

- Industrial chemicals and fine pharmaceuticals Process design

- Process control

- Process operations

- Process Economics

Track 12 - Chemical Kinetics and Catalytic Activity

Chemical kinetics is also named as the reaction kinetics, and which is the branch of physical chemistry that is concerned with perceptive rates of chemical reactions. When it is compared with the thermodynamics, approaches the direction in a process. It explains about insignificant rate, and the study of Chemical kinetics in this method. The experimental conditions impacts the speed of a chemical reaction and yield information, then the reaction's mechanism and transition states, are also the construction of mathematical models defines the characteristics of a chemical reaction.

- Transient Kinetics

- Single site catalysis

Track 13 - Catalysis in Nanotechnology

Heterogeneous catalysts are commonly recognized as Nanomaterial-based catalysts, and in that Heterogeneous catalysts are destroyed up into metal nanoparticles in command to recover the catalytic process and Metal nanoparticles must have high surface area, which can increase the catalytic activity. Nanoparticle catalysts are easily detached and recycled. This are commonly used under mild conditions to prevent decomposition of the nanoparticles. When it compacts with immediate rising field of Nanotechnology catalysis. It includes the usage of nanomaterial’s as a catalysts, and it used for a modification of homogeneous and heterogeneous catalysis applications. Heterogeneous catalysis that suggests one of the eldest commercial practices of nanoscience, nanoparticles of metals, semiconductors, oxides, and other compounds has been broadly used for important chemical reactions.

- Nanotubes, nanofibers and nanoparticles

- Carbon nanotechnology

- Nano-Flake Technology

- Microscopic & spectroscopic characterization

- Green nanotechnology

Track 14 - Enzyme and Microbial Technology

Enzyme and Microbial Technology is the basic and functional characteristics of biotechnological processes including the use of enzymes, microorganisms, and animal and plant cells.

- Industrial microbiology

- Bacterial culture

- Virus and phage culture

- Eukaryotic cell culture

- Microbial Biotechnology

- Microbe-Mineral Interactions

Track 15 - Fluid Mechanics

The branch of physics concerned with the mechanics of fluids and forces on them are known as a fluid mechanics. When the applications is in extensive range of disciplines, including civil, mechanical, chemical and biomedical engineering, oceanography, geophysics, meteorology, astrophysics, and biology are discussed in fluid mechanics.

- Fluid statics

- Fluid dynamics

Track 16 - Catalysis for Renewable Sources

The production of renewable energies, and surrounding areas of knowledge from fuel cells to biofuels, biomass and waste valorisation, solar energy, low temperature catalytic transformation of triglycerides and fatty acids are obtained from the renewable feed stocks, which represents a key enabling technology for the sustainable manufacture of biodiesel through energy efficient, and deepened processes. The usage of renewable energy in transient to increase the smarter use of biomass.

- Efficient use of non-renewable resources

- Waste reduction, waste capture and recycling

- Catalysis for water treatment and remediation

Track 17 - Catalysis for Biorefineries

In a bio-based economy the various products of the chemical industry, which are presently based on fossil resources, are need to be formed from renewable resources. Similarly to the petrochemical refineries, in which crude oil is first fractionated and later managed in numerous, and highly integrated value chains to various petrochemicals, renewables would be treated are known as a bio-refineries. Biorefineries are becoming progressively important in providing a sustainable ways for chemical industry processes, and for the formation of bio-economic models, depends on biorefineries, used for the development of advanced products are highly combined value such as biochemicals and bioplastics. It also permits the development of "green chemistry"approaches synergy with traditional chemistry. When it decreases the heavy dependence on imports and contributions of the development, economically and environmentally sustainable production processes that provides the huge investments, and research, innovation efforts.

- Algal fuels and Bio products

- Hydrogen and Fuel cells

- Natural Gas and Crude Oil

- Advanced Biofuels

- Biofuels Market and Future

Track 18 - Petrochemical Engineering

The branch of Chemical Engineering which is concerned with the operations are included in refining petroleum or crude oil, by the usage of advanced technology is known as Petrochemical Engineering, which also included in the extraction of crude petroleum are attained from the core of earth. The mechanism and techniques are convoluted in activities like exploration, production and exploitation of oil or natural gases. Petrochemicals are also named as petroleum distillates. When chemical products are attained from petroleum by refining. Specific chemical compounds are made from petroleum are also achieved from other fossil fuels, such as natural gas, or coal or renewable sources, maize, palm fruit or sugar cane.

- Petrochemistry

- Petroleum refinery

- Natural gas conversion

- Biomass conversion and biorefinery processes

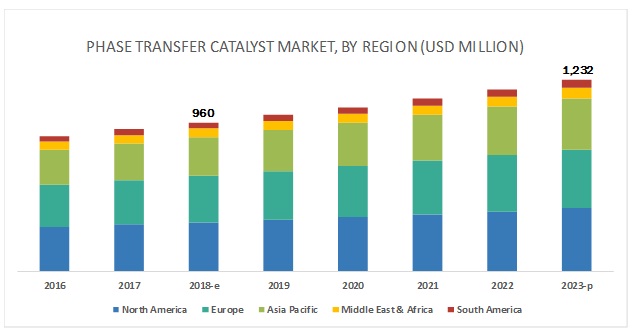

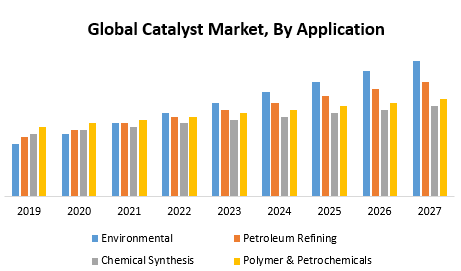

According to a new report work by Grand View Research, Inc. the global catalyst market size is predictable to reach USD 34.1 billion by 2025, showing a 4.5% CAGR through the forecast period. Increasing the use of catalysts for manufacturing of petrochemical products is influence in the market.

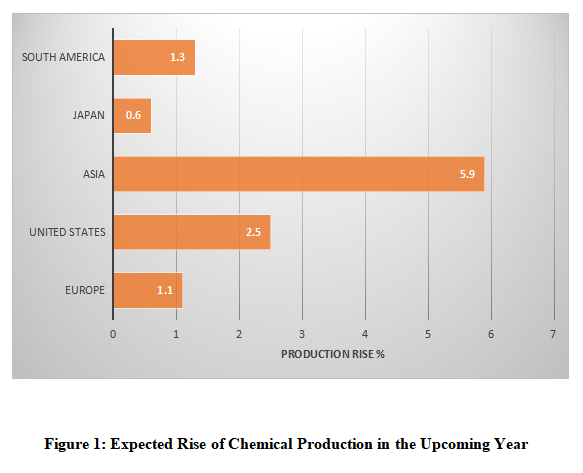

The Worldwide market for Chemical Catalyst is predictable growth at a CAGR of approximately 5.9% finished the next five years, then it will reach to 7640 million US$ in 2024, from 5740 million US$ in 2019, according to a new Research work.

This report emphasis on the Chemical Catalyst in global market, especially in North America, Europe, and South America, Asia-Pacific, Middle East and Africa which classifies the market depends on manufacturers, regions, type and application. and the Chemical Catalyst market succeeds as one of the most proactive industry verticals.

Market Segment by Manufacturers,

- Johnson Matthey

- Clariant AG

- BASF SE

- Honeywell International

- Evonik Industries

- CRI

- Grace

- Sinopec

- Albemarle Corporation

- JGC Catalysts and Chemicals

- Ineos Group AG

- Univation Technologies

- Lyondell Basell Industries

Market Segment by Regions, regional investigation covers that:

- Europe (Germany, France, UK, Russia and Italy)

- North America (United States, Canada and Mexico)

- Asia-Pacific (Japan, China, Korea, Southeast Asia and India)

- South America (Brazil, Argentina, Colombia etc.)

- Middle East and Africa (Egypt, Saudi Arabia , UAE,Nigeria and South Africa)

Market Segment by Type, covers

- Supported Metal Catalyst

- Polyolefin Catalyst

Zeolite Catalyst Market Segment by Applications, can be divided into

- Polymerization Catalyst

- Fine Chemical Catalyst

- Petrochemical Catalyst

Applications Insights

The chemical synthesis division was esteemed at USD 6.7 billion in 2018 and is predictable to grow in future owed to growing demand from many end-use industries. Chemical synthesis includes organic chemistry and inorganic, including procedures such as contact, Haber, and conversion of ammonia to nitric acid that needs use of catalysts. Development of the chemical industry on a global scale is also predictable to fuel product demand. Catalysts are broadly used in chemical synthesis owed to properties such as, activation of alkynes and alkenes, enantioselective processes and promotes diastereo-, regio-,and high stability. Furthermore, they hold properties similar as excellent efficient group tolerance, no need for additional ligands, and cost competitiveness, which is also predictable to drive the segment.

Conference Highlights

- Fundamentals and types of Catalysis

- Biocatalysis and Biotransformation

- Advanced Synthesis, Catalytic Systems and New Catalyst Designing

- Industrial Catalysis and Process Engineering

- Reaction Engineering

- Green and Sustainable Catalysis

- Organometallics, Organocatalysis and Bioinorganic Chemistry

- Chemical Engineering

- Novel Concepts of Catalysis and Applications

- Novel Reactors & Process Intensification

- Academic-Industrial Catalysis Research

- Chemical Kinetics and Catalytic Activity

- Catalysis in Nanotechnology

- Enzyme and Microbial Technology

- Fluid Mechanics

- Catalysis for Renewable Sources

- Catalysis for Biorefineries

- Petrochemical Engineering

To share your views and research, please click here to register for the Conference.

To Collaborate Scientific Professionals around the World

| Conference Date | November 16-17, 2020 | ||

| Sponsors & Exhibitors |

|

||

| Speaker Opportunity Closed | Day 1 | ||

| Poster Opportunity Closed | Click Here to View | ||

Useful Links

Special Issues

All accepted abstracts will be published in respective Our International Journals.

Abstracts will be provided with Digital Object Identifier by